An alloy based on iron is called iron sheet. Iron sheet is composed of different materials, each of which is used in different parts of the construction industry and other industries.

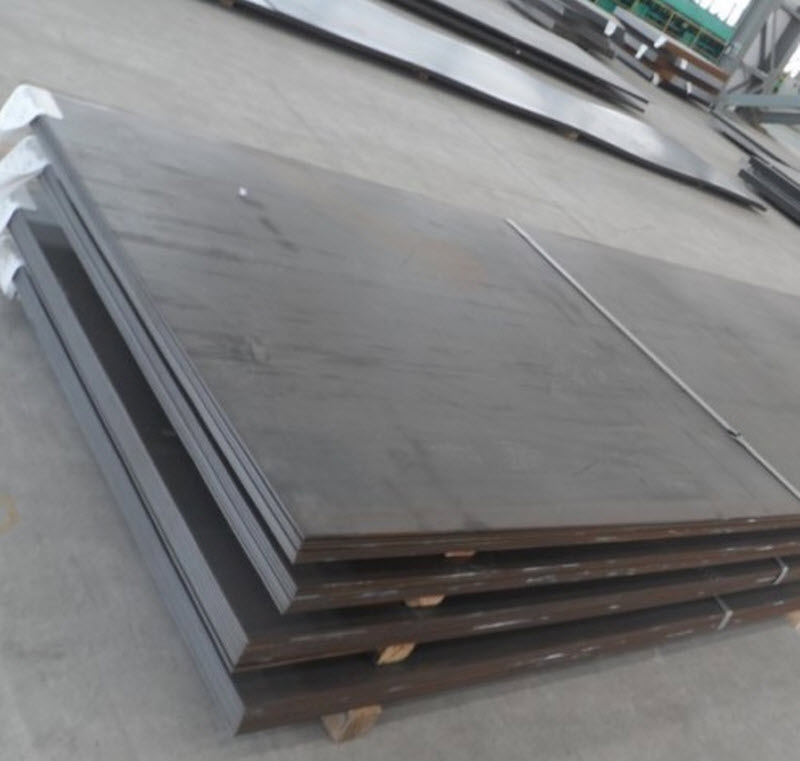

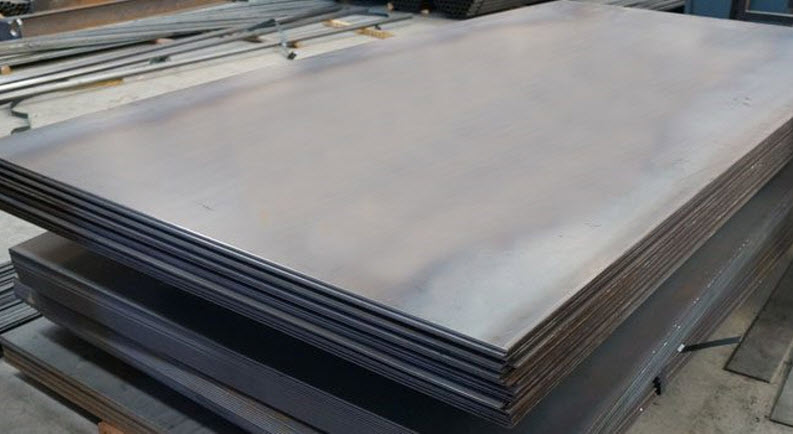

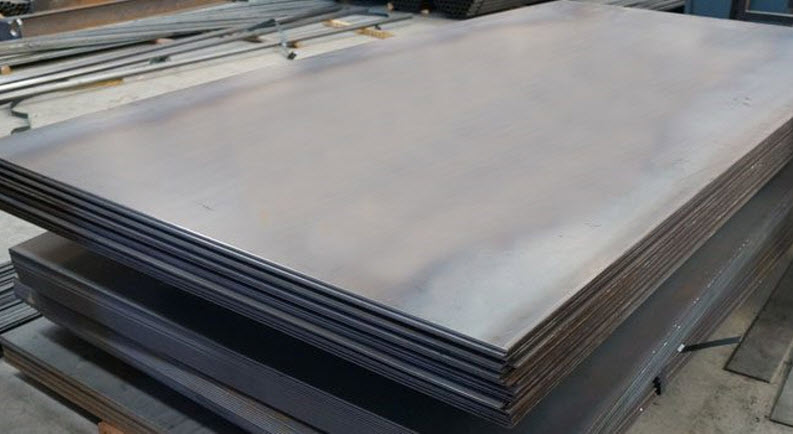

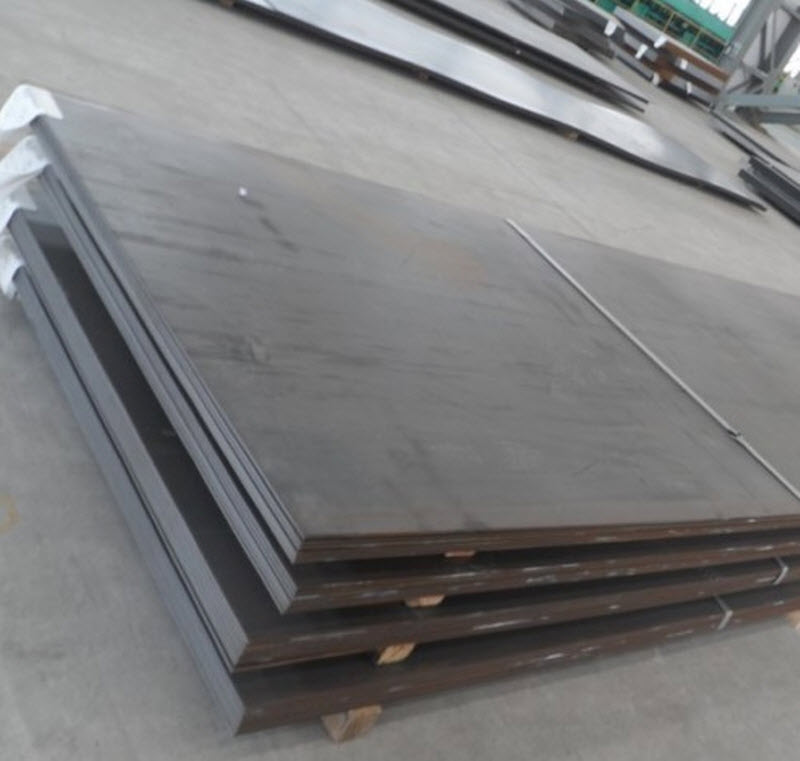

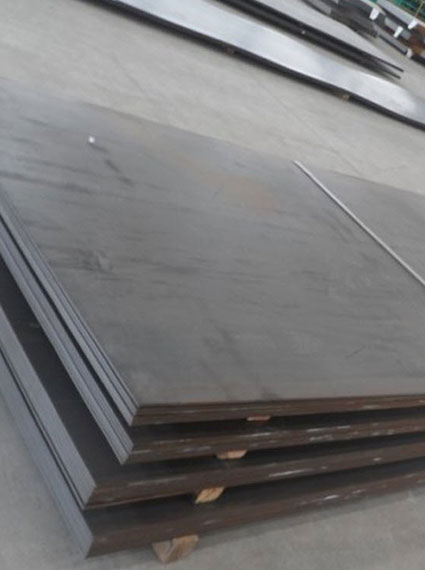

Black iron sheet

Sheets produced by hot rolling are called black sheets. Black sheet is one of the main iron sheets available in the market, and an index called ST is used to measure its quality, this index is between numbers St33 and St52 in normal black sheet. This designation is based on the amount of carbon in the iron sheet materials, so that the St 33 sheet has the lowest amount of carbon and therefore the most flexibility compared to other qualities and the ST52 sheet has the highest amount of carbon and therefore the most flexibility. it is little Also, ST37 sheet and ST52 sheet are the most widely used black sheets in the market, which are highly regarded in the construction industry.

oiled sheet

Iron sheet is divided into two categories: cold rolled sheet and hot rolled sheet. As we said, the output product of hot rolling is black sheet, and the output product of cold rolling is called oil sheet. Oil sheet, which is also known as cold steel sheet in the market, has a standard width of 100 and 125 cm and is produced in thicknesses of 0.3 mm to 4 mm. Oil sheets are actually the basis of making galvanized sheets.

Since steel pipes have a strong and strong structure, they are used for infrastructure such as sewage, gas transmission from refineries, water transmission throughout cities and towns, etc.

The galvanized pipe has a molten zinc coating, therefore it has a high resistance to moisture. Manisman pipe is a seamless pipe that is used to transport oil and gas.

Black iron sheet

Galvanized sheet is an iron sheet that is covered with zinc metal on their surface. Galvanized sheet is used in many cases, such as the production of cooler channels, the roof of water pipes and places where there is a possibility of contact with water and corrosion. In addition, one of the most common uses of galvanized sheets is the production of colored galvanized sheets and colored roofing sheets, which are produced and supplied in various colors and sizes.

color sheet

It is a type of galvanized sheet, which is also called colored galvanized sheet because its base sheet is galvanized. Colored sheets are first baked in the oven. Galvanized steels have a coating of zinc oxide that protects the sheet from environmental factors. Without this zinc coating, the metal may oxidize or rust. This zinc coating added to the sheet makes the galvanized sheet resistant to scratches and fingerprints, and allows for better handling during shipping and installation. The color will not be damaged and a shiny and clean surface will be available to you.

Gable color sheet

The colored sheet of gable is a galvanized sheet with zinc coating. The way to paint these sheets is the same as the colored sheet, and the main difference with the colored sheet is in the variety of its forms and shapes, which are:

Sinusoidal shutter sheet

Pottery design sheet

Shadowline sheet

Trapezoid sheet

Gable hedge sheet

Each of the colored sheets of gable has its own unique use according to its form, but in general, it can be said that the main use of these sheets is covering the roof and wall of sheds, buildings, villas, etc.

The standard thickness of these sheets is 0.50 to 0.60 mm, and the price of gable sheets is determined according to the thickness and type of the manufacturer. Among the other features of these galvanized sheets, we can mention the variety of colors, beautiful appearance, low thermal conductivity coefficient, corrosion resistance, and its affordable price, which is considered a kind of cheap galvanized sheet.

Our other products

Black iron sheet

An alloy based on iron is called iron sheet. Iron sheet is composed